Customized Fit Instead of One-Size-Fits-All

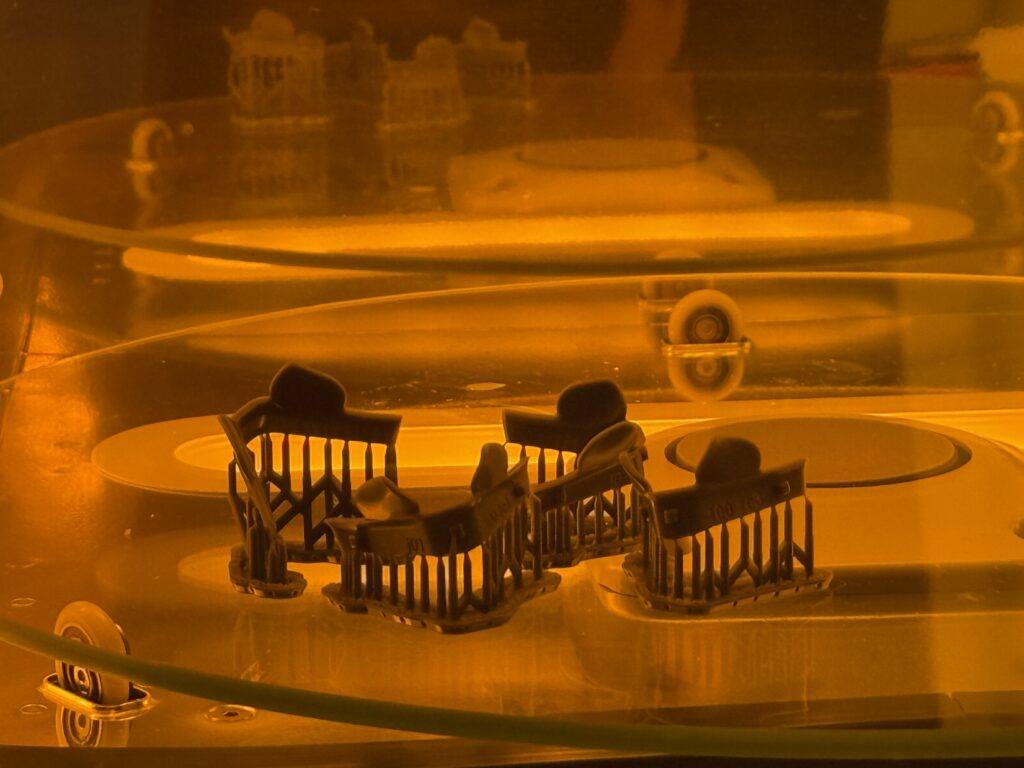

With SLA 3D printing, we create nose pads that precisely match each individual’s nose shape. A 3D scan of your face provides the necessary data, the printer produces the customized component – ready in just a few hours. This approach accommodates anatomical features that would otherwise cause pressure points or slipping with standard components.

What Is SLA 3D Printing?

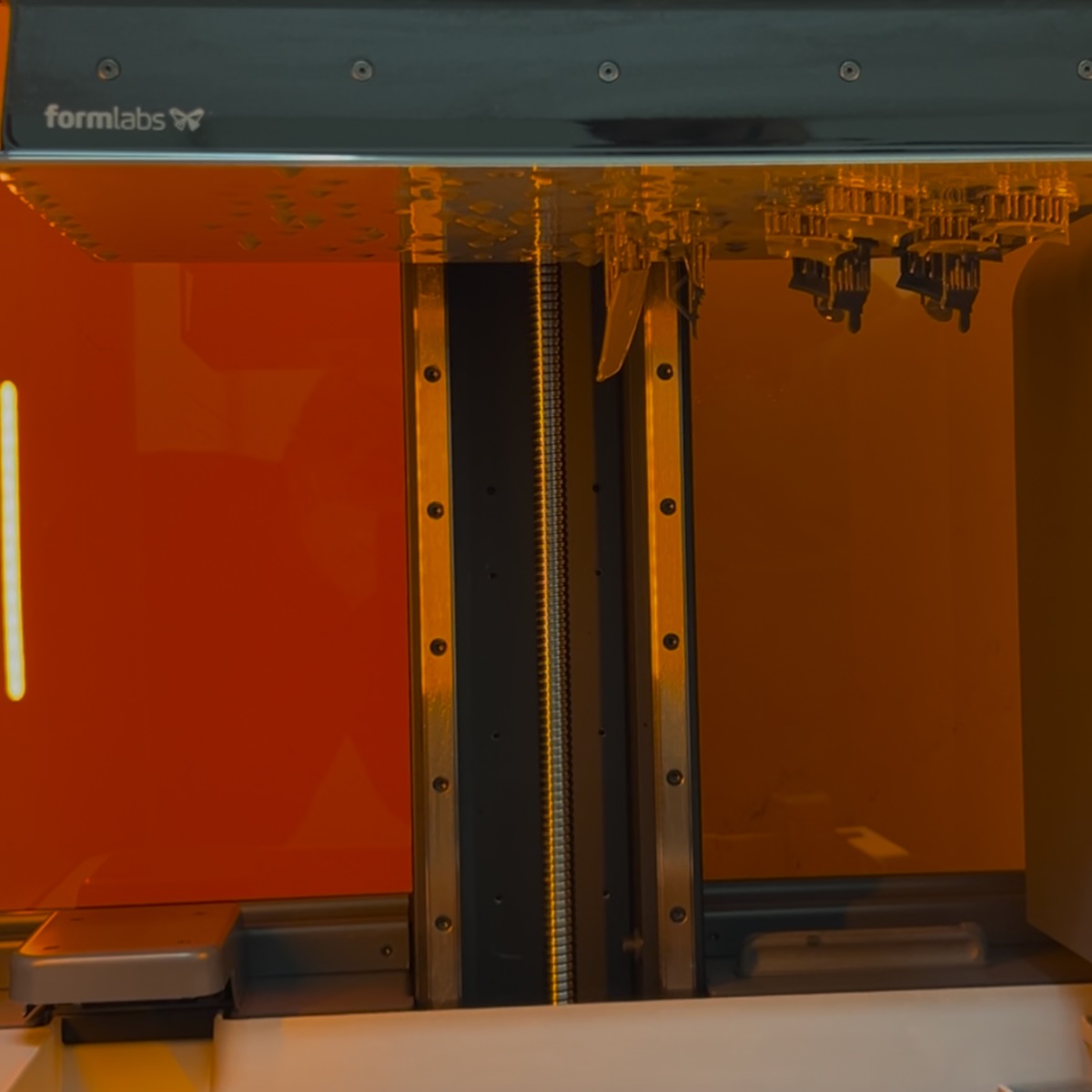

SLA stands for stereolithography, one of the most precise 3D printing processes available today. Unlike FDM (Fused Deposition Modeling) printing, where molten plastic is applied layer by layer, SLA uses liquid resin that is cured by UV light.

Here’s how it works: A UV laser or LCD screen exposes the liquid resin with pinpoint accuracy. Where the light hits the material, it hardens. Layer by layer, the desired component is built – achieving precision within a few micrometers.. We use Formlabs Tough 1500 – a special resin that is both flexible and robust.

Why use SLA 3D Printing for Individual Eyewear Components?

The technology offers three key advantages: speed, with finished parts ready in just a few hours; precision, achieving micrometer-level accuracy, and a smooth, skin-friendly surface – ideal for components that rest directly on the skin.

SLA particularly demonstrates its strengths with small, delicate components such as nose pads or temple arms. The materials are flexible enough to adapt to each person’s nose shape, yet robust enough for daily use in sports or at work. The smooth surface is skin-friendly and comfortable.

The Complete SLA Production Process: Liquid Resin Meets UV Light

From digital concept to finished component, each part passes hrough three stations. This standardized process ensures onsistent quality and optimal material properties.

Phase 1: The SLA Printer – Building the Component, Layer by Layer

The production process begins with a 3D file – either from a CAD program or a 3D facial scan. This file is divided into thin layers, which the printer creates one by one.

What happens in the printer?

The build platform dips into the liquid resin, and UV light exposes the first layer with pinpoint accuracy. The exposed material hardens, then the platform rises by one layer thickness. This process repeats until the component is complete.

Depending on size and complexity, the printing process can take anywhere from 30 minutes to several hours. However, the finished part is not yet ready for use at this stage. It is covered with liquid resin and only partially cured.

Phase 2: The Wash Station

After printing, the component is covered with uncured resin. This must be removed, otherwise sticky residue can remain, affecting the surface and preventing the material from fully curing.

Phase 3: The Curing Station – Final UV Curing

After cleaning, the final step is complete curing in the curing station. Here, the component is fully cured using a combination of UV light and heat, achieving its final strength values.

From Concept to Perfectly Fitting Smart Glasses

SLA 3D printing brings three key advantages:

True Individualization: Every part can be adapted to the wearer’s specific anatomy – without expensive tools or molds. This enables true mass customization, even for small batches or one-off productions.

Speed: From concept to finished part in just a few hours – not days or weeks. Multiple design iterations can be completed within 24 hours: a nose pad design printed in the morning, tested in the afternoon, adjusted, and the improved version printed in the evening.

Precision: Micrometer-accurate manufacturing ensures components fit perfectly and provide maximum comfort – especially important where standard components don’t fit well.

This approach has become the standard at leading technology companies: Microsoft, for example, uses SLA printing in its Advanced Prototyping Center to test multiple design variants quickly.

With SLA 3D printing, we can create smart glasses like the VPSNext that not only impress. technologically but also fit perfectly – achieving a level of quality that would have been unthinkable just a few years ago.

Interested in customized components for your smart glasses?